Weld Build Up and Machining of ID Fan Bearing Housing Project

Weld Build Up and Machining of ID Fan Bearing Housing Project

When you need a field service company to weld repair and machine your critical equipment, call us today. Check out these images of a recent project weld build up and machining of ID fan bearing housing we completed at EKPC....

Mobile Machine Shops

Mobile Machine Shops

We have two fully equipped mobile machine shops for turbine support to include: stud removal, line boring, seat removal and installation, seat power lapping restoration, welding “R” stamp, alignment key machining. Call us when your tool box needs a little help getting to location. ...

Single Point Machining Combined Reheat Stop/Intercept Valve Seat

Single Point Machining Combined Reheat Stop/Intercept Valve Seat

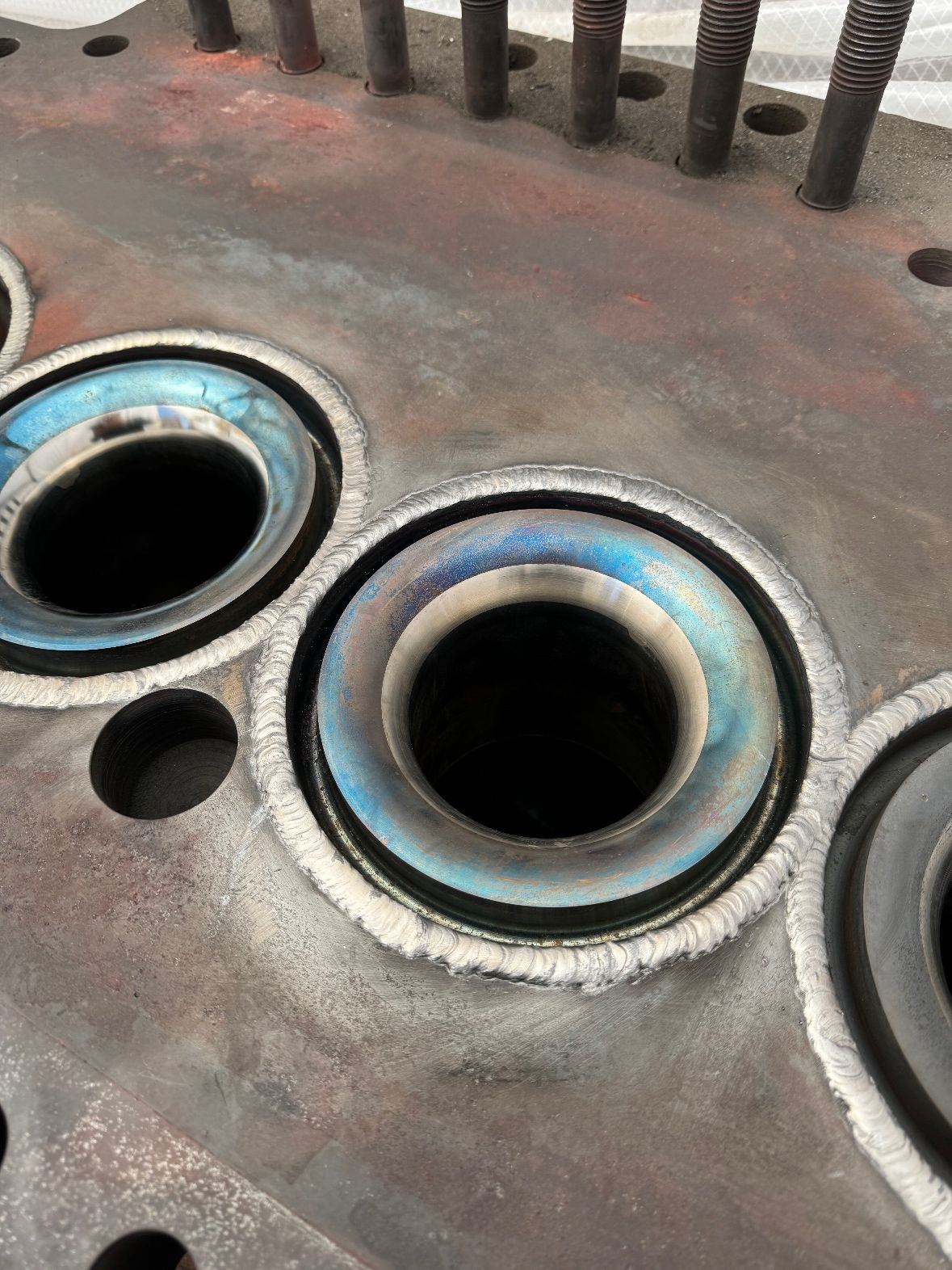

Single point machining combined reheat stop/intercept valve seat at Vistra Luminant GE 900 MW turbine in Texas. Just one of many seats now restored back to design specs by the Turbine group at T&W....

Seat Repair for a Westinghouse Intercept Valve

Seat Repair for a Westinghouse Intercept Valve

We specialize in turbine valve seat repair and replacement. Recently at Vistra Luminant, we completed a seat repair in a intercept valve on a Westinghouse 800 MW unit. This involved in place weld build up and machining to restore a radius seat. We are able to restore the seats on GE, Westinghouse an...

Precision Turbine Valve Seat Restoration

Precision Turbine Valve Seat Restoration

We specialize in lapping, replacing, or machining turbine valve seats to meet your needs. Recently, we successfully replaced two seats and repaired three others on the BFP Turbine. All seats had been incorrectly installed initially. Despite the challenge, we completed the task within six shifts....

Optimizing Turbine Valve Surfaces

Optimizing Turbine Valve Surfaces

Following the machining of the seating surface on a combined intercept/reheat stop turbine valve, we proceeded to machine the pressure seal head surface of the reheat stop using the same setup. This ensured all surfaces were squared and the valve was properly centered....

© Copyright 2022. T & W Valve And Machine Co., Inc. All Rights Reserved. Industrial Website Catalog by WYSIWYG Marketing